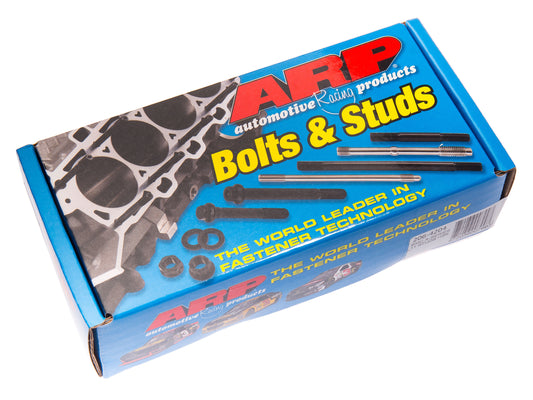

ARP CONROD BOLT KIT

Description

ARP conrod bolt kits are sold in engine sets for Cooper S, regular 1275 or 998 conrods. These are a direct replacement for the standard fixings.

Upgrading the standard conrod bolts is essential for any performance engine build, as these are far more resistant to stretch than the standard items. We would recommend these for all engine rebuilds.

- Cooper S - 3/8" bolts and nuts - 42lb.ft

- 1275 - 11/32" bolts and nuts - 35lb.ft

- 998 - 3/8" bolts - 42lb.ft

For reference, original Cooper S and 998 conrods are designed to run on 1.625" diameter big end journals, whereas 1275 are 1.750".

MG Midget 1275 engines require Cooper S bolts whereas Rover Mini Cooper S conversions used the later A+ crankshafts, so opt for '1275' bolts.

For all other small-bore engines (850-1098), choose the 998 bolts.

Frequently Asked Questions

What is the material spec?

These bolts are machined from ARP2000, an alloy steel with a tensile strength of 220,000 PSI. ARP2000 is used widely in motorsport applications as an upgrade from 8740 chrome moly in both steel and aluminium rods. Stress corrosion and hydrogen embrittlement are typically not a problem, providing care is taken during installation.

Can ARP conrod bolts be re-used?

If they have been installed and torqued correctly, and show no visible signs of damage, then yes they can be re-used. However if they show any signs of thread galling or corrosion, or have stretched by 0.001" or more, you should replace them. Typically race engine builders will install new conrod bolts during each rebuild for peace of mind; on a road-going engine with lower RPM, they are subjected to less severe forces and should last longer.

What are the recommended torque settings?

ARP recommends the 3/8" fixings (Cooper S and 998) should be torqued to 55lb.ft, but we would advise 42lb.ft. The 11/32" fixings should be torqued to 35lb.ft. Preferably these should all be checked using an ARP rod bolt stretch gauge and stretched to 0.0065"-0.0070".

What is the advantage over standard A-Series conrod bolts?

The standard conrod bolts may have been torqued up, or even over-torqued and stretched many times already, so refitting them is a big risk. The ARP bolts are also made from a higher grade of steel that's far less prone to stretching, making this a sensible upgrade for performance use.

Can I use ARP bolts on a standard engine?

Yes, the ARP conrod bolts will work on a standard engine, lightly tuned for the road or right up to full-race spec. Just make sure to select the correct design to suit your engine, using the information above.

Related Products