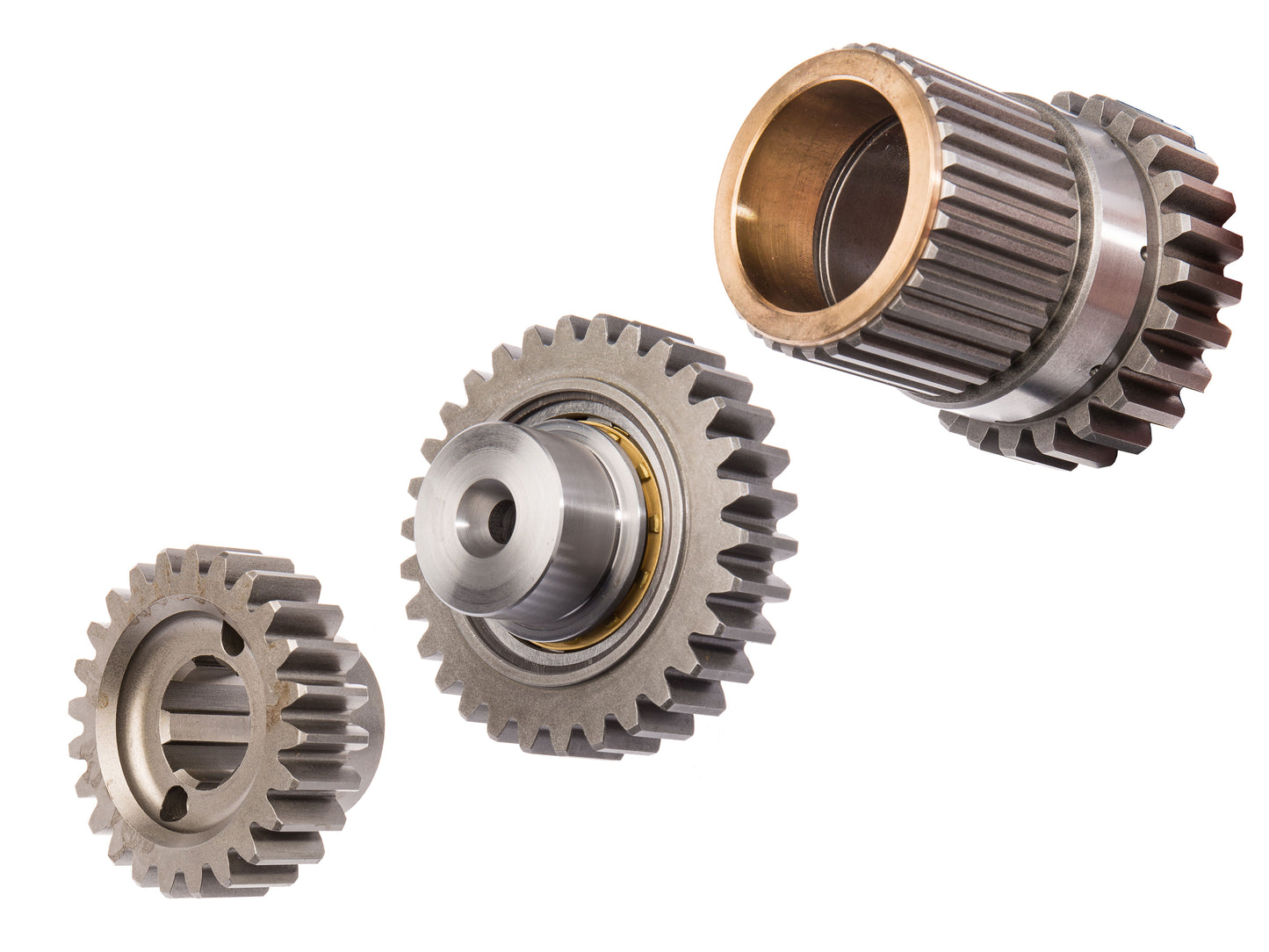

MED S/C DROP GEAR SET - ROLLER TYPE

Description

A must for any competition engine build, the MED roller bearing drop gear sets use a highly durable roller bearing/spindle design for the idler gear.

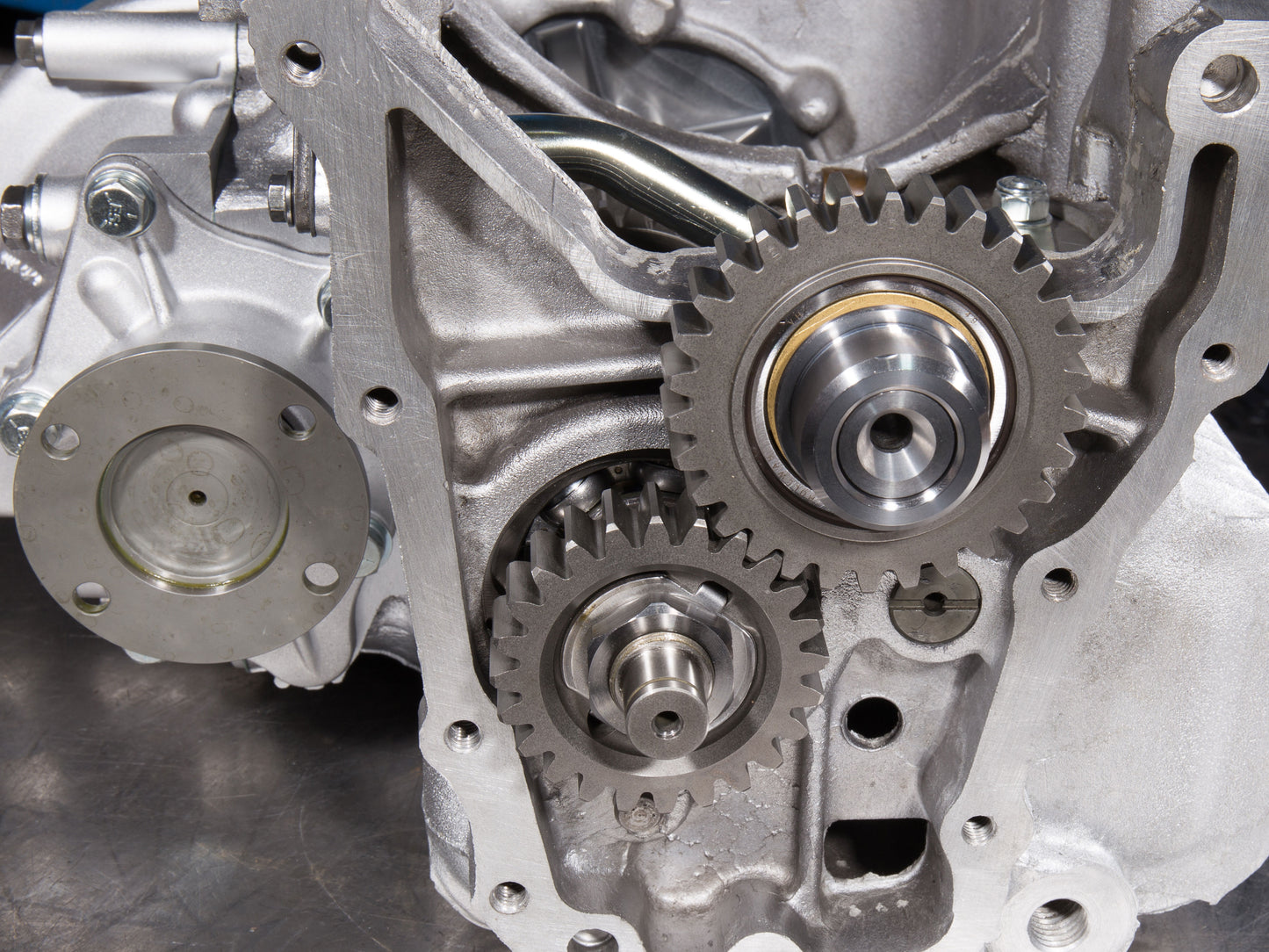

The idler gear roller bearing runs on the steel support shaft fitted into the gearbox casing, with a steel top hat spacer to replace the idler bearing within the flywheel housing, which encapsulates the idler gear assembly when fitted. There is no need for any idler gear shimming, as all tolerances are taken up within the gear assembly.

Straight-cut drop gears are stronger and more reliable than the standard helical design, with less side-loading effect.

MED roller bearing drop gear features

- Primary gear tooth width is now 17.2mm long, an increase of 2.4mm, to give more contact area between the primary gear and idler gear to greatly reduce tooth wear.

- A fully-floating primary gear bush, which is retained by a flat section circlip to help reduce primary bush failure.

- The idler gear has an integral roller bearing, running on fixed axis within the gearbox and flywheel housings – probably the strongest and most reliable available for the A-Series transmission.

- Extra wide input gear teeth to give greater tooth contact between both idler gear and input gear, again to help reduce tooth wear.

Gear set choice

We can supply alternative ratio sets by changing the primary gear/input gear. See the Additional Information tab for more on changing drop gear ratios. If you're happy with your current gear ratios, select the 1:1 option.

Both 1275cc and 998cc sets can be chosen from the dropdown menu above. For reference, A-plus sets have a 22mm idler gear shaft and pre-A-plus have a 19mm idler shaft.

For fast road applications we would recommend setting the primary and idler gear end float between 0.004-inch to 0.006-inch. For competition, a marginally larger tolerance may be suitable - contact us if you're unsure.

Additional Information

The MED drop gear sets are available in three different ratios, which can be used to tweak the final drive ratio. Changing the effective final drive ratio will either improve acceleration or top speed potential, although one will always come at the expense of the other.

We can do this by changing the tooth count on either the idler gear or primary gear to 23 or 24 teeth. The idler gear in the middle remains at 30 teeth regardless.

The table below shows the various tooth counts and the effect on the drop gear ratio:

| Drop gear set configuration | |||

| 1:1 | 1:1.043 | 1:0.958 | |

| Input gear | 24 teeth | 24 teeth | 23 teeth |

| Idler gear | 30 teeth | 30 teeth | 30 teeth |

| Primary gear | 24 teeth | 23 teeth | 24 teeth |

To calculate your effective final drive ratio based on the above, simply multiply your existing final drive ratio by the number of the drop gear set. So for example, a 3.47:1 final drive ratio with a 1:1.043 drop gear set then becomes 3.62:1. Remember that the higher the number, the shorter the gearing will be, so this change will result in a higher engine RPM for a given speed.

Changing the primary gear is easier than removing the differential to change the final drive ratio, so racers use this to adjust their gearing to suit different circuits. Keeping an engine in its peak powerband for longer will result in a faster lap time.

See the following table for our final drive conversions using the various drop gear sets:

| Drop gear ratio adjustment | ||

| Original final drive |

With 1:1.043 drop gears |

With 1:0.958 drop gears |

| 3.47:1 | 3.62:1 | 3.32:1 |

| 3.75:1 | 3.91:1 | 3.59:1 |

| 3.875:1 | 4.04:1 | 3.71:1 |

| 4.066:1 | 4.24:1 | 3.90:1 |

| 4.2:1 | 4.38:1 | 4.02:1 |

| 4.5:1 | 4.69:1 | 4.31:1 |

Related Products