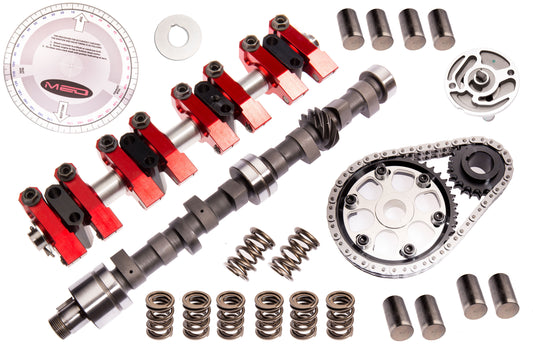

MED ST1 CAMSHAFT KIT

Technical Video:View More

Description

All MED camshafts are machined from new steel blanks, never re-profiled, so you can be assured of the highest quality product. Our three profiles have been developed specifically for road use with over 35 years of A-Series experience.

The Stage 1 kit comes with the following components;

- Cross-drilled billet camshaft (apart from MPi)

- Chilled iron cam follower set

- Camshaft lock tab

- Steel-backed oil pump

- Camshaft timing disc

Camshaft profile choice;

-

MED HT - An excellent road camshaft, 256/256 duration with a power band from 1000-6000rpm

-

MED RS - Our Road Sport camshaft, 270/284 duration with a power band from 1250-6500rpm

-

MED XT - Our track day camshaft, 280/280 duration with a power band from 2500-7250rpm

-

MED MPi - Designed for fast road multi-point injection Minis, 252/264 duration, power band from 1500-6500rpm

- MED T3 - Special forced induction camshaft, 264/276 duration with reduced valve overlap

Frequently Asked Questions

Which camshaft should I choose?

It's entirely dependant on your driving preferences and the spec of the other engine components. Road trip mile muncher or daily driver? The most civilised HT profile would be ideal. Fast road car for country lane blasts? RS makes a good compromise. Fast road/trackday/rally car for the weekend? Go for the XT. A more conservative camshaft spec can often result in a more enjoyable driving experience on the road, as the peak power band is lower in the RPM range.

How much power can I expect?

It's impossible to answer without knowing the exact spec of the engine and the quality of the rebuild. However, for a rough guide, if we were to take an identical 1380cc high performance road engine with a modified head, re-worked crankshaft, single HIFF44 carburettor and 1.5:1 roller rockers, the following peak outputs could be expected: HT - 100lb.ft/100bhp, RS - 100lb.ft/106bhp, XT - 100lb.ft/112bhp.

Which engines will this fit?

All BMC A-Series and A-plus engines, with the exception of eight-port head conversions. Standard 850 engines do not use camshaft bearings, so you will need to line-bore the block and fit bearings to run one of these cams.

Can I change my camshaft in situ?

It has been done on 998 engines and 1275 Cooper S blocks with the removable tappet chest covers, as you can just about change the followers in-situ, but we wouldn't recommend it. On a regular 1275 you will not be able to change the followers without dismantling the engine.

Do I need to fit 1.5:1 rockers?

Our camshaft profiles have all been optimised to work below 1.5:1 rockers, but it's not essential. We also supply 1.3:1 ratio rockers to cater for personal preferences and all engine builders have their own tastes. The 1.3 rockers can help to reduce emissions, which may be useful on a '90s Mini.

Do I need double valve springs?

Ideally, yes. Our uprated road spring sets are highly recommended to remove the chance of valve bounce at higher RPM. These are available separately or as the Stage 2 camshaft kit.

How about adjustable cam timing setup?

It's essential; without adjusting the camshaft timing to suit the new profile, you will not be able to optimise engine performance. Stage 2 comes complete with an adjustable vernier duplex timing kit.

Should camshaft choice vary between 1275 and 'small bore' engines?

Yes, we typically find that the 998/1098 engines work better with a more conservative camshaft profile (less lift and duration) compared to the 1275. So if you are considering the RS profile for a 998, you may prefer the performance of the HT, for example. Generally, for the best results, step down one profile when building a small-bore engine.

Related Products