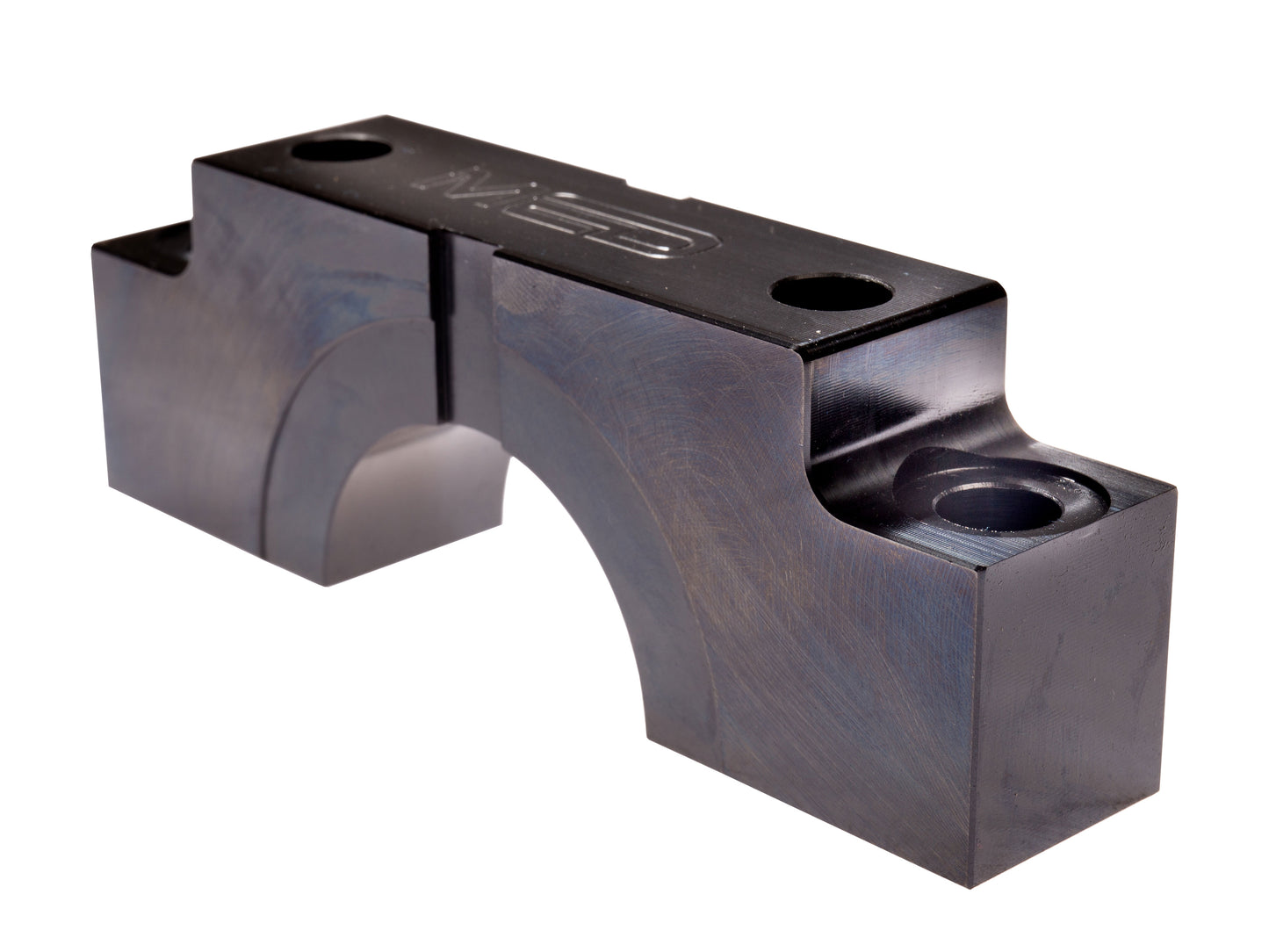

MED 4-BOLT STEEL MAIN CAP

Description

The MED four-bolt steel main cap adds much strength to the centre of the block where crankshaft 'whip' is most prevalent. For reliability, we consider this upgrade essential for any high RPM race engine.

Designed for all 1275 engines (excluding the original Cooper S), the cap is CNC machined from EN8 steel stock and supplied with a pair of dowels.

Please note, the block will need to be drilled/tapped to accept the outer two fixings and then line-bored.

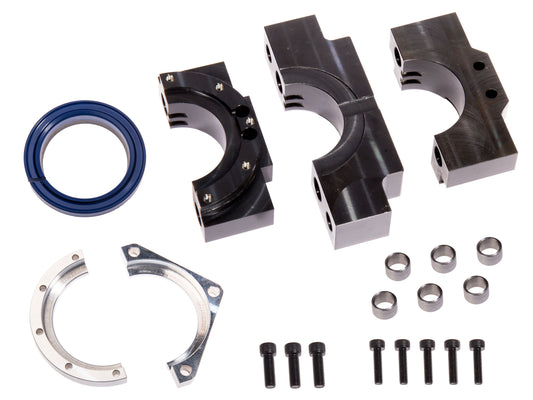

You may wish to consider the complete MED steel main cap set.

We'd highly recommend using the MED AFS main stud conversion rather than standard bolts.

Frequently Asked Questions

Will MED steel main caps fit all Mini A-Series engines?

These are designed to fit 1275 blocks, including both A-Series and A+ varieties, but excluding the original 1960s Cooper S blocks, which had studs and steel caps from the factory. They will fit other transverse A-Series engines such as Metro and Austin 1300GT too. For inline applications we keep a different set of steel main caps to suit.

What is the fitting procedure?

We would recommend starting with the MED AFS stud kit, modifying the block to accept the four-bolt centre main and checking, drilling and tapping the existing threads to level-up the studs. From here, the block and caps will need to be line-bored and hone finished by a specialist machine shop, with the thrust washer faces machined flush to the block.

Do I need to install a full set of steel main caps?

Generally it is recommended to fit a full set, as the machining cost and time will be very similar on one cap to three. That said, these have still been quite popular over the years as a standalone item.

Can I fit steel main caps to a road-going Mini engine?

Sure, if the budget allows. These come highly recommended for any high RPM A-Series; we'd consider them essential on a competition engine that's driven to sustained high RPM levels.

Related Products