ARP HEAD STUD FIXING KITS

Technical Video:View More

Description

We consider ARP fixings an essential upgrade over the standard or budget aftermarket studs, which are prone to stretch. If the studs stretch, it's impossible to accurately torque down the cylinder head, leading to potential gasket failure.

This comprehensive kit includes the main head studs, rocker pedestal studs and all washers and nuts required. It is available for either nine or 11-stud head applications.

Kit contents:

- 4 x long head studs

- 7 (or 5) x short head studs

- 11 (or 9) x 3/8" UNF multi point nuts

- 9 (or 11) x heavy duty washers

- 4 x rocker pedestal studs

- 4 x 5/16" UNF multi point nuts

- 4 x rocker pedestal washers

- 1 x ARP fastener lube

ARP recommends a torque of 45lb.ft on the 3/8-inch head stud nuts, however we usually go to 50lb.ft. Torque the 5/16-inch rocker pedestal nuts to 25lb.ft. The studs themselves should only be hand tight.

Please see the additional FAQ tabs for more detail.

Be particularly wary of imitation ARP kits online - these are the genuine article.

Frequently Asked Questions

What is the advantage of ARP head studs on an A-Series engine?

The standard-grade head studs were made to a lower price point and are prone to stretch, which can lead to inaccurate torque settings, and subsequent head gasket issues. This is especially apparent for original studs that have been torqued down regularly over many years, or subjected to adverse conditions - i.e. left in a damp garage or out in all weathers.

What torque setting should be used?

ARP recommends a torque of 45lb.ft on the 3/8-inch head stud nuts, however we usually go to 50lb.ft. Torque the 5/16-inch rocker pedestal nuts to 25lb.ft. The studs themselves should only be hand tight - the hex in the end of the stud is to ease installation, not to apply torque. However, it is extremely important to ensure that the studs are fully bottomed out in their holes in the block and not hung up on damaged or corroded threads, preventing them from being fully seated. This is often indicated when the stud threads extend past the deck surface.

Can I re-use ARP head studs?

As long as the fasteners have been installed and torqued correctly, and show no visible signs of damage, they can be re-used. If they show any signs of thread galling or corrosion, they should be replaced.

What grade of steel are these machined from?

These studs are machined from ARP2000, an alloy steel with a tensile strength of 220,000 PSI. ARP2000 is used widely in motorsport applications as an upgrade from 8740 chrome moly in both steel and aluminium rods. Stress corrosion and hydrogen embrittlement are typically not a problem, providing care is taken during installation.

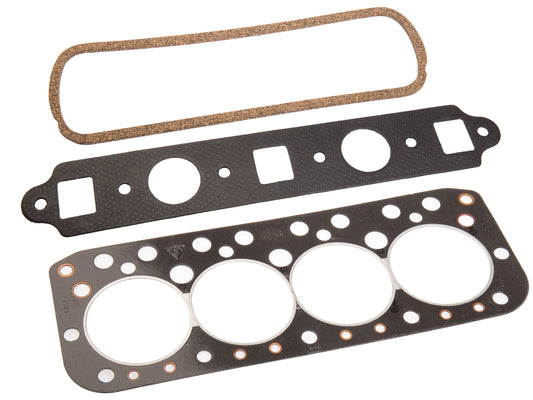

Are there any A-Series-specific fitment tips to look out for?

After test fitting the studs in the block, it is generally easier to remove them, put the head gasket and head on the block and re-install the studs. This will reduce the possibility of damaging the upper threads of the studs, and make head gasket fitment much easier. We would also recommend counter-boring the very top of each thread in the block, to avoid movement of the block deck face when tightening each stud nut, which can give head gasket sealing issues.

On the 11-stud kit, are the two extra stud threads as per the Cooper S?

No, on the S blocks, the water pump end had a threaded insert and 5/16" thread and bolt. The ARP kit has a full set of 3/8" UNC studs, so the block will need to be drilled and tapped to suit. We always recommend installing the 11th head stud at the water pump end of the engine with a coating of silicone sealer, as this protrudes into the water jacket. Failure to do this may result in a coolant leak.

Related Products