MED DRY DECK KIT COMPLETE

Description

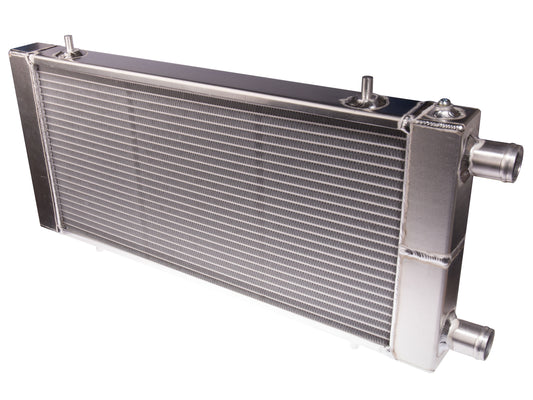

The MED dry-deck kit aims to improve cooling efficiency across the block and head, which is particularly useful on hot-running performance engines or those in warmer climates.

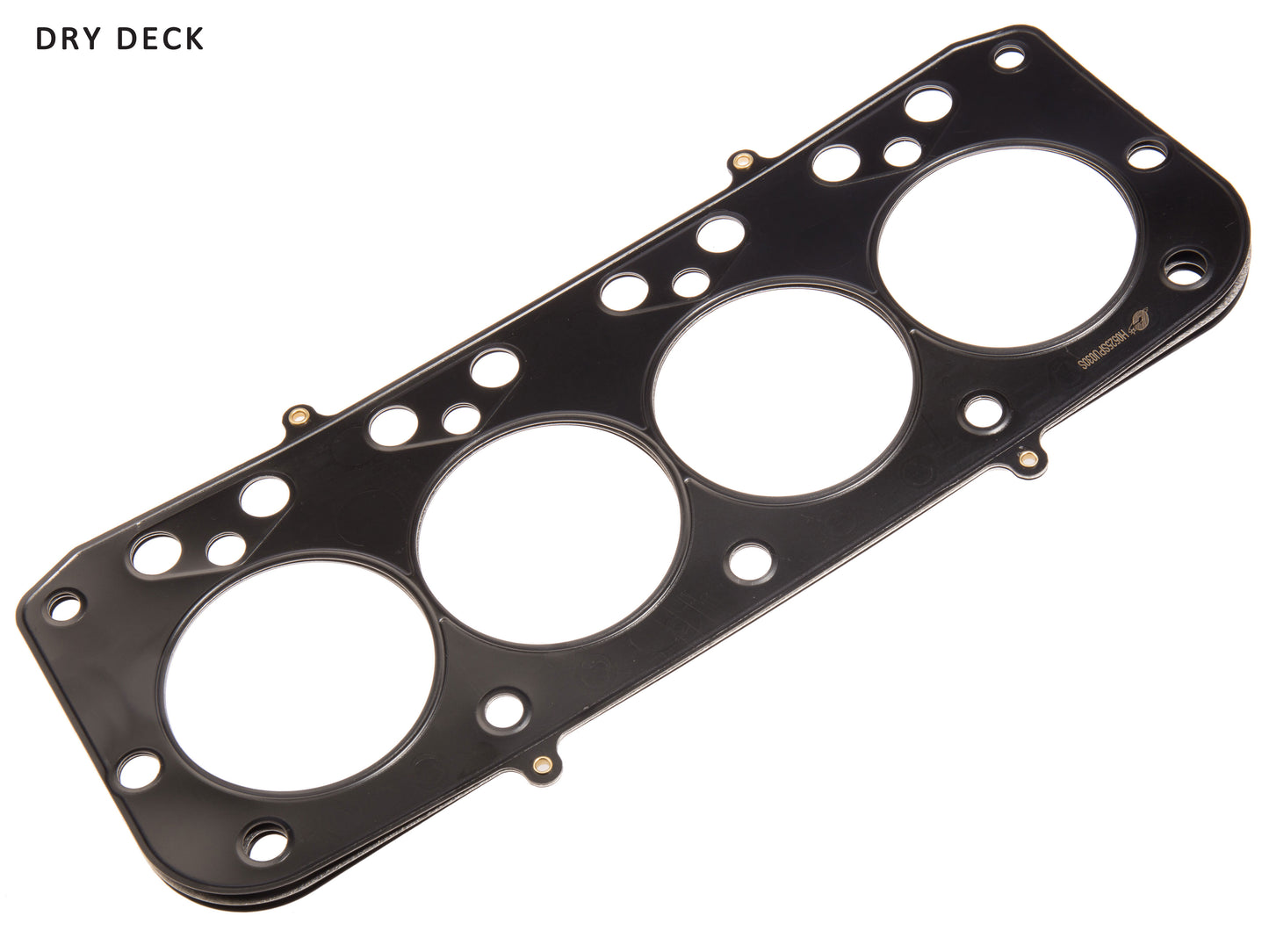

Our kit includes a steel-shim head gasket with blank water gallery holes, saving much machining time and cost to blank the original water galleries in the block.

The +20,40,60 head gasket will suit engine sizes from 1275cc to 1330cc. The 73.5mm option is a special offset-bore gasket to suit 1380/1460cc engines.

Kit contents:

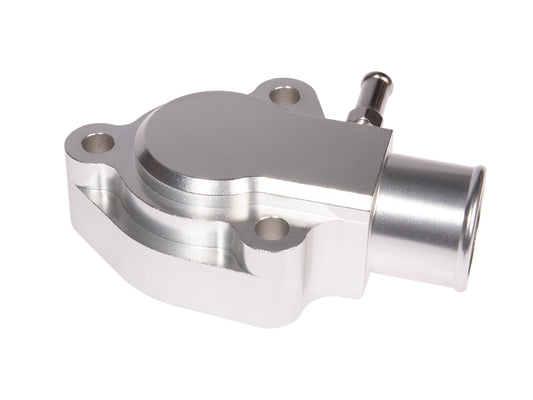

- 2 x aluminium adapters

- 1 x bespoke steel shimmed head gasket

- 1 x silicone 180-degree hose

- 4 x Allen cap bolts

- 2 x stainless steel hose clips

The engine outlet fitting will require a small cut-out to fit around the engine steady fixing, to be machined after drilling and tapping of the block.

We also recommend a light file of the edge of engine number tag location - just enough material for the gasket to sit flush.

Frequently Asked Questions

Why would you dry-deck an A-Series engine?

'Dry decking' refers to the process of blocking some or all of the coolant transfer ports between the cylinder head and block, re-directing coolant flow to more evenly maintain temperatures across the engine. On a competition Mini engine, we find that cylinder number four, furthest from the water pump, tends to suffer from excess heat build up. Dry decking re-routes the coolant flow along the block, out of the engine via a 180-degree hose and back through the cylinder head.

How do you dry-deck an A-Series engine?

There are a few different ways to complete this conversion. Either modify the cylinder head with brass bungs to restrict flow of coolant, modify the block, or use a special steel-shim gasket such as this one, with the waterways blocked off. The end core plug will need to be removed and this face drilled and tapped for the supplied hose take-off. On the cylinder head, the end will need to be spot faced and drilled to suit the second take-off. The supplied screws are M5, standard 0.8mm pitch.

Will this suit all A-Series engines?

We would usually recommend this for Mini/Metro applications only, as the Sprite bell housing can hinder access. It's most effective on high performance or competition engines that generate excess heat, or those driven hard in warmer climates.

Can I buy the gasket or the hose and adapters separately?

Yes, the dry-deck kit can be found as part number MED-1930-DH, and if you look at the head gasket section of our website, you'll find the steel-shim gaskets listed separately.

What is the compressed volume of the head gasket?

If you're trying to calculate compression ratio, we would use 3.01cc for the '20,40,60' gasket, and 3.15cc for the 73.5mm option. Both gaskets are 0.030" thick.

How does the hose take-off adapter fit around the top engine steady?

Once the adapter position is decided upon, you will need to file a notch in the block adapter for clearance of the engine steady bracket.

Related Products