MED VERNIER CAMBELT DRIVE

Technical Video:View More

Description

The MED Vernier Belt Drive kit replaces the traditional timing chain setup with a high quality Gates belt, aiming to dampen any potentially damaging harmonics from the valve train. It is easily adjustable to perfect camshaft timing in situ.

The updated design removes the tensioner to allow for a more compact setup, therefore enabling fitment on both Mini and inline (Sprite/Midget) engines. This unique new design uses a Mini primary gear oil seal for the camshaft and a readily available seal for the crankshaft.

Features:

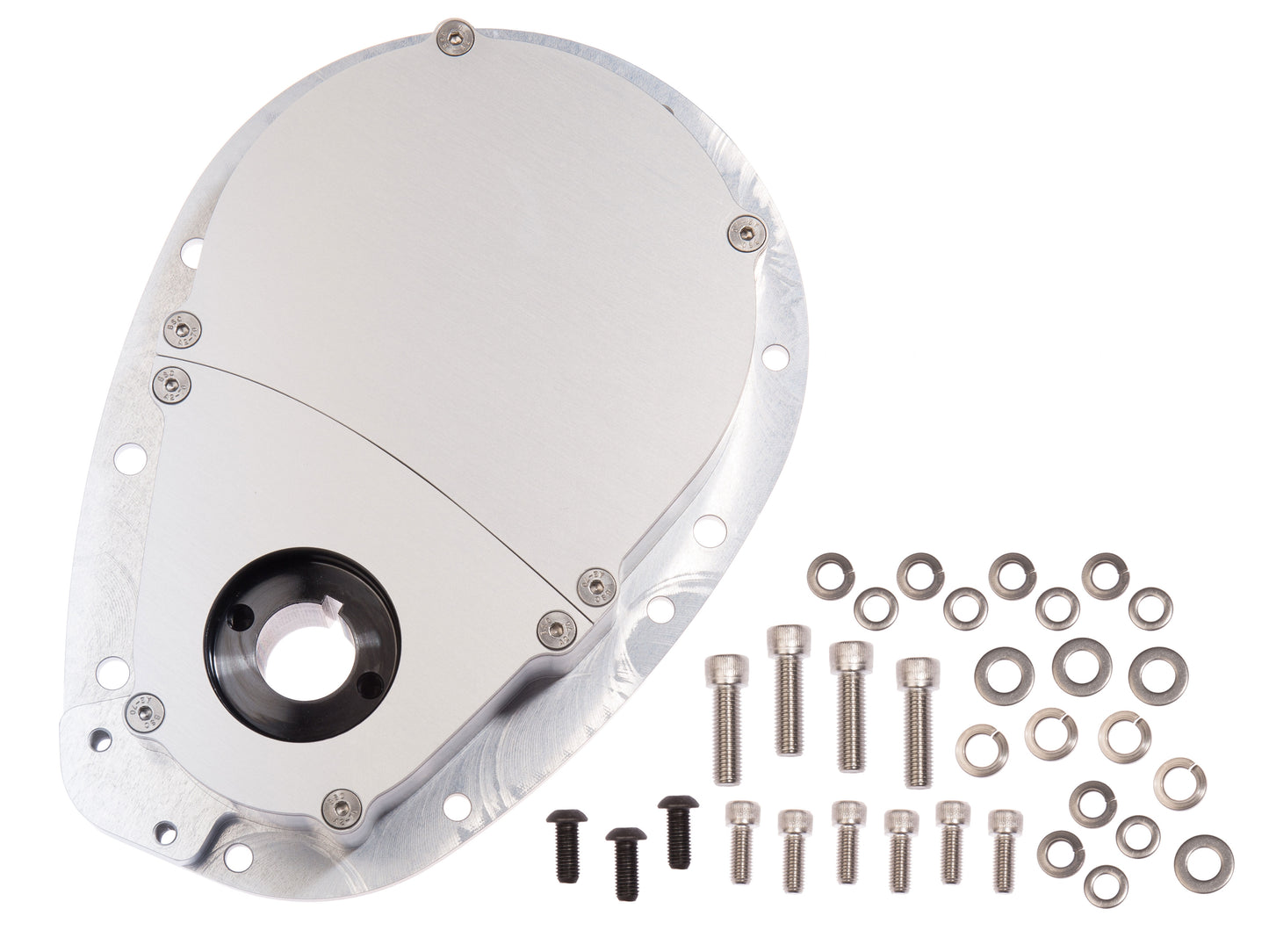

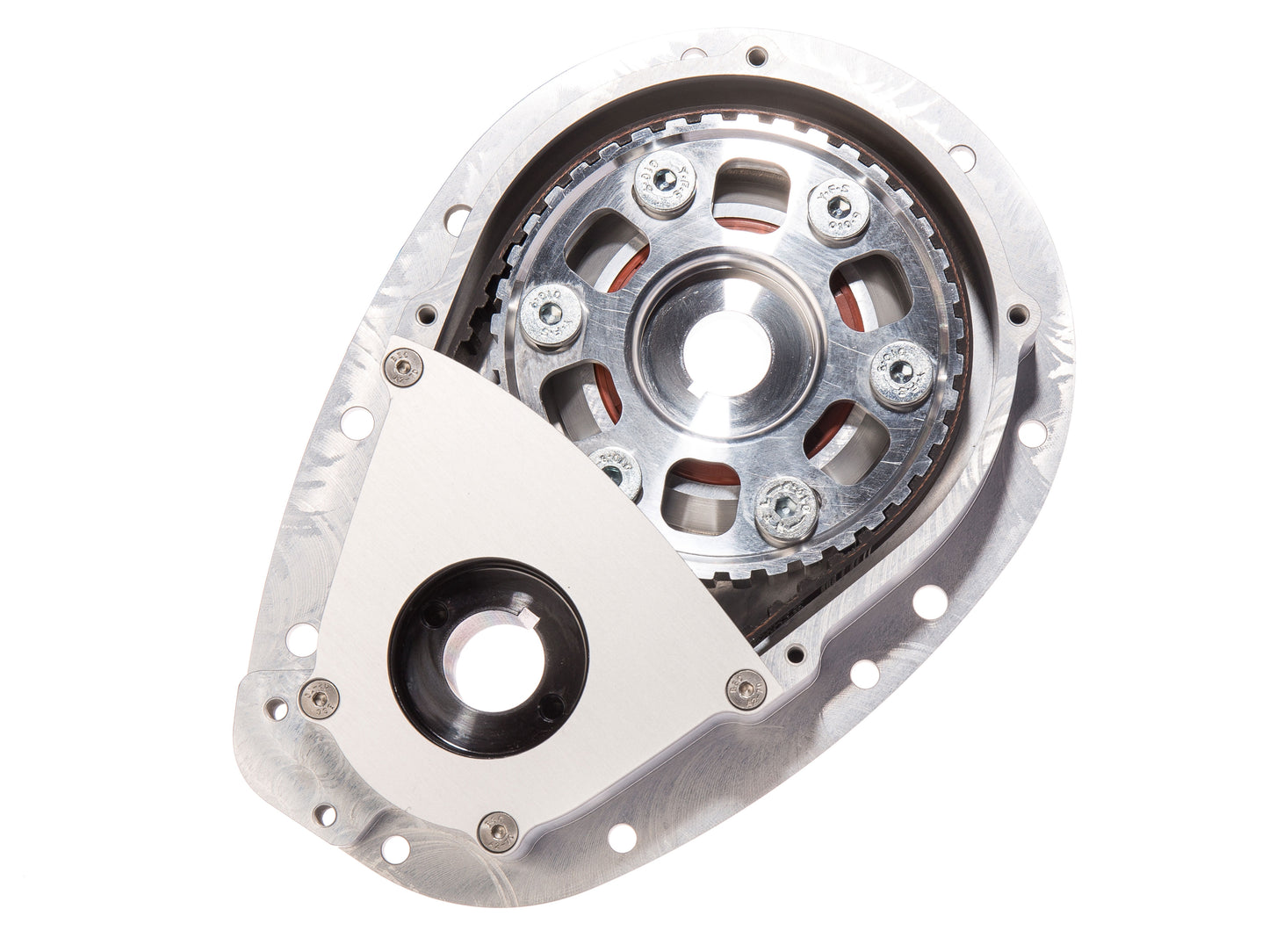

- CNC-machined aluminium housing with removable cover to enable access to camshaft timing without removal of the crankshaft pulley.

- Large diameter crankshaft pulley with belt retaining rails to retain rigidity along the key way and resist cracks.

- Adjustable camshaft vernier pulley machined from 7075 aluminium.

- Easily available oil seals for both camshaft and crankshaft.

- Compatible with standard timing plates or the upgraded MED aluminium Mini timing plate.

- Mounting holes for optional crank position sensor bracket, for engine management systems.

Optional extras:

Please note - this kit does not fit MPi Minis, as the crankshaft pulley sits further inboard and touches the outer cover.

Frequently Asked Questions

What's the advantage of using a cambelt on an A-Series engine?

Weight - the belt is considerably lighter than a chain. For comparison, the belt in our kit weighs around 37g, where a duplex chain is 400g. Another advantage of the rubber belt is its ability to effectively dampen harmonics from the valvetrain. It's also much easier to adjust the cam timing in-situ, as the housing is sealed from the engine oil, so the split cover plate can be removed to access the vernier-adjustable cam pulley. All of these benefits make the kit well suited to competition engines.

Where would a timing chain kit be better suited?

Usually for high-mileage road cars in a lower state of tune where a fit-and-forget solution is preferred, and the performance benefits of the belt are less crucial. The cambelt must be changed more frequently than a chain.

How often does the belt need to be changed?

We would recommend changing the belt once a season for full-competition use, or using for up to five years on a road-going A-Series engine. The belts will no doubt last longer than this, but for the relatively low cost of replacement, it's best to be safe. To change the belt, the lower crank pulley needs to be removed, then the front cover.

Is this a wet belt design?

No, the housing is sealed from the engine and the belt must not be subjected to oil. Fitting tips are included in the box to help with correct assembly and setup.

How is the cam timing adjusted?

It's a very similar setup technique to our vernier adjustable timing chain kit, where the camshaft pulley has an adjustable centre section. This allows the camshaft timing to be infinitely advanced/retarded in relation to the crankshaft, then locked in position with the six fixings.

Does this fit all A-Series engines or just classic Mini?

Yes this kit will suit all A-Series engines, including inline applications such as Sprite, Midget and Minor. The only exception are MPi Rover Minis, the very last production cars, as these run a multi-rib lower crankshaft pulley and it fouls on the outer case.

The pulleys are a bit tight on my camshaft and/or crankshaft - what shall I do?

Firstly, test fit the pulleys before you install the outer casing. We make this kit to suit all A-Series engines, and there can be a huge variety in tolerance on the end of the crank and camshafts. The sprockets should be a snug fit, but not so tight that they need excess force to fit. Remove the steel keys and check for burrs. Try the sprockets in place with the keys removed, and if too tight you will need to lightly hone the centre bores to a give a snug fit.

Are there markings to help set the ignition timing?

Yes, there are marks engraved on the cover for reference, but these must not be taken for granted, as different crankshaft pulley/dampers will have a TDC mark in different places. Get the engine set to TDC and mark across to the pulley. Alternatively we can supply the kit with a special 3D printed pointer, or even a crank position sensor kit if you plan to install mapped ignition.

Related Products