MED S PULLEY MANAGEMENT - FLAT

Description

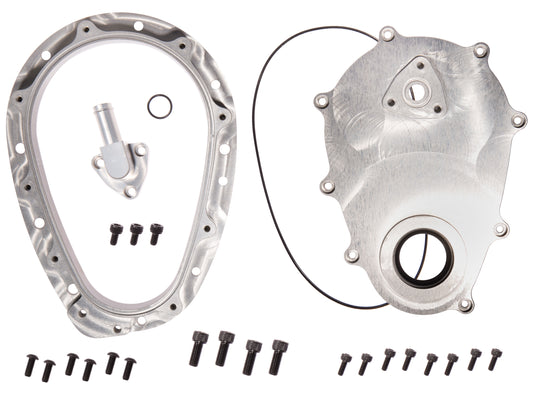

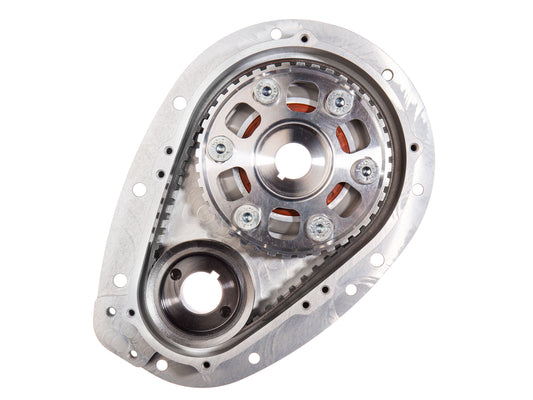

Our lightweight steel billet crankshaft pulley is a direct replacement for the original, with the option to bolt on a large MED Dynamic Damper Ring for improved crankshaft vibration damping.

There are 36 integral teeth for engine management systems, requiring the removal of one tooth to suit your ECU setup. This is the neatest trigger wheel setup available for the A-Series engine and one of our most popular products.

The flat style is specifically designed for use with the MED Cambelt Kit, the MED Cam Timing Cover or a BMW ‘K’ engine conversion.

If you wish to install the damper, it's best purchased as a complete balanced MED S Damper Kit with bolt and washer.

The pulley suits regular V-belts and will fit all A-Series engines apart from the final MPi Minis.

We also produce an accompanying crank position sensor kit.

Frequently Asked Questions

Does this suit all A-Series engines?

Yes, apart from the very last MPi Minis, as these run a multi-rib belt in place of the traditional V-belt. This particular pulley is designed to work alongside the MED Cambelt conversion or the MED Alloy cam timing cover.

How do the management teeth work?

Mounted alongside our MED-1402-CPSB crank position sensor kit, the sensor sends a pulse signal to a suitable ECU each time a tooth passes close by. With 36 teeth on the pulley as standard, you will need to remove one tooth to give the desired 36:1 pattern. This allows the ECU to register each crankshaft rotation by sensing the gap, which should be positioned relative to engine top dead centre.

How should I remove the tooth?

We tend to use a small rotary grinder to remove the chosen tooth, then apply a brush of paint to prevent corrosion. Be very careful not to touch the adjacent teeth, as any variations can send a false reading to the ECU and cause running issues.

Which tooth do I need to remove?

It depends on the ECU, so please check in with the manufacturer and they will be able to advise. You'll usually need to install the pulley and count the teeth from the sensor with the engine at TDC, to determine how many degrees before or after TDC the gap should be. Remember that each tooth equates to 10 degrees. Some ECUs will allow you to offset this in the software if it is not quite right, but best to get it right first time if you can.

Why is this called an 'S Pulley'?

It stems from the design of the original two-piece Cooper S crankshaft pulley and damper.

Do you have any fitting advice?

The pulley should be a snug fit on the crankshaft tail, but if you find it is too snug, do not just tighten the bolt and hope for the best. Firstly remove the crankshaft key and re-try the pulley in place. If it is still too tight, there may be a burr on the end of the crankshaft that will need to be addressed. If it now fits well, take a look at the key and ensure it can be fitted squarely back into the crankshaft and is also free of any burrs. On certain brand new steel crankshafts, occasionally you may need to lightly hone the centre bore to give a good fitment. If the pulley is too loose, be careful as the tail of the crankshaft may be worn.

What size screws will I need to fix this to the crankshaft damper?

We use 5/16" UNF x 1" with a flat washer and the lock tab.

Do I need to balance the pulley?

Ideally have the pulley balanced once the tooth has been removed. If you do decide to install the optional MED damper, then this is best balanced as an assembly.

Can I use the standard pulley bolt?

Yes, either that or our uprated bolt, part number MED-1410-CB, which has a longer thread for better engagement.

Related Products