MED S DAMPER KITS

Technical Video:View More

Description

The MED S Damper Kit comes assembled, balanced and ready to fit with a longer heavy-duty crankshaft bolt and washer.

The kit combines our popular MED Dynamic Damper Ring with a crankshaft pulley of your choice, precisely assembled and balanced in-house on our aerospace-grade machine. All pulleys work with a regular V-belt.

Kit contents:

- MED dynamic damper ring

- MED S pulley of your choice

- Fixings

- MED heavy-duty damper bolt and washer

- Pulley lock plate

Pulley choice:

- Regular - standard replacement pulley kit, distributor ignition.

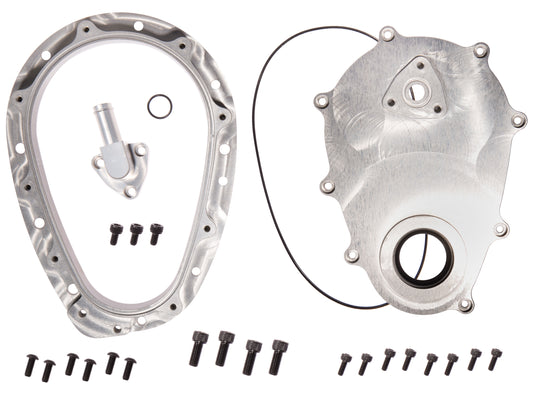

- Management - integral 36:1 teeth for a crank position sensor kit and standard timing cover.

- Management flat - as above, but to suit the MED cambelt, MED alloy cam timing cover or 16-valve engine.

If you'd like a crank position sensor to accompany the management pulley, please see the MED crank position sensor kit for a standard timing cover, or the MED cambelt crank position sensor kit for one of our cambelt kits or cam timing covers.

Torque the bolt to 70lb.ft, with a dab of regular strength threadlock. For extra fitting tips and advice, please see the Additional Information tab.

Additional Information

Fitment tips

- To ensure the pulley is a snug fit on all engines, in some cases light honing of the centre bore may be required. If fitment is too tight, check for burrs on the end of the crankshaft tail and also the key.

- Check that the large crank bolt does not bottom-out in your crankshaft thread before fitting the pulley. On rare occasions, the thread may not be fully tapped and the longer bolt may bottom out before the pulley is tight.

- Apply a small amount of medium strength thread lock to the large crank bolt and torque to 70lb.ft

- Now mark the position of the damper to the pulley before removing the four cap head screws, to maintain the balance.

- The lock plate installs over the central bolt, and is fixed in place by the four cap head screws. Apply a small dab of thread lock and re-torque to 18lb.ft

- For ignition timing setup, turn the engine to TDC and mark across from the timing bracket (if fitted) to the damper with a paint pen or scribe. This position will vary from one timing cover to another.

- For engine management, check where the missing 36:1 tooth needs to sit in relation to the position sensor when the engine is at TDC. Mark the tooth, remove the pulley from the damper, noting the position to maintain balance, and remove the chosen tooth. This should not significantly affect the balance.

Frequently Asked Questions

Does this suit all A-Series engines?

Most of them. The only exceptions being the very early inline A-Series with a starter handle bolt on the end of the crankshaft pulley, and the very last MPi Minis. The kit will still suit the early inline cars, but you'll loose the handle connection, if that's an issue. Unfortunately for MPi Minis, these run a multi-rib belt so the pulley system is not compatible. Otherwise it suits all engine sizes and fitments.

What is the purpose of this kit?

The large damper helps to reduce and absorb torsional vibrations of the crankshaft assembly, which are particularly problematic on the A-Series engine with only three main bearing journals. Many A-Series engines were supplied with a crankshaft damper from the factory, but over time, exposure to oil, heat and general engine bay grime, the rubber can disintegrate and cause more trouble than good. These are much more robust.

Will this fit in an MG Midget or AH Sprite?

Yes, but on rare occasions you may find it sits a bit close to the front crossmember, depending on how far forward the engine is positioned. You may wish to lightly machine this panel for clearance in this situation, and to allow easy replacement of the fan belt.

Why is this called an 'S Damper'?

It stems from the design of the original two-piece Cooper S crankshaft pulley and damper.

Are there any clearance issues on a Mini?

Usually not, no. On certain cars we have found the radiator bracket around the engine mount sits quite close to the pulley, so a light modification of this bracket with a file will help fan belt replacements. We have seen on certain aftermarket radiators where the lower hose angle is not correct, the hose can sit very close to the damper. If the radiator is standard, or one of ours, it will not give problems here.

Are there any fitting instructions available?

Yes, there's paperwork in the box with fitment tips, and also above, if you check out the 'Additional Information' tab.

Which pulley type will I need?

If your car has a distributor-type ignition system, as standard, select the 'Regular pulley' option. If you wish to install engine management on your A-Series engine and have a standard timing chain cover, select the 'Management pulley.' For those with an MED Cambelt conversion or MED billet alloy timing cover, choose the 'Management - flat' option. You will need to purchase the crank position sensor kit separately.

What is the difference between this and buying the S pulley on its own?

This kit comes complete with everything required to fit, and we balance on our rig to within 0.5g. It's the best option unless you already have some of the components.

What is the diameter of the damper?

This is 150mm in diameter, or approximately 5.9".

Related Products