OMEGA FORGED PISTONS 73.5mm - SHORT HEIGHT

Description

Omega/MED forged pistons are the lightest and strongest on the market, with a narrow-section ring pack to reduce friction and ultra-light 18mm gudgeon pins to further reduce weight.

Exclusive to MED in 73.5mm bore sizes, 7cc dished or flat-top crowns with various short compression heights to suit longer conrods and/or long-stroke crankshafts.

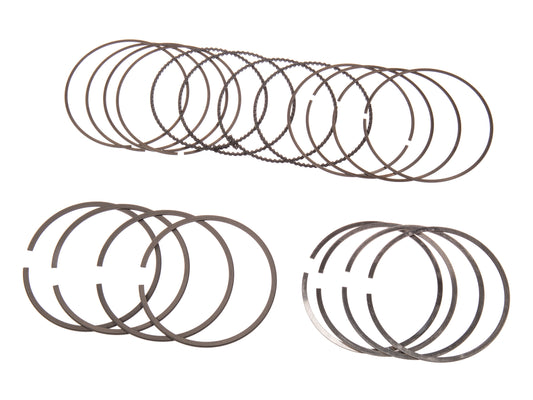

Supplied as a balanced set of four with gudgeon pins, clips and piston rings, which are also available separately if you require spares.

Tech spec

- 73.5mm for the 1275 engine (1380/1460cc)

- Super lightweight design

- High strength for full competition usage

- Offset 7cc dish crown, with flat-top option in 1.248" height

- Made in the UK exclusively for MED

- 1.248", or super short 1.115" compression heights

- Lightweight 18mm floating gudgeon pins

Please see the additional information tab for more detail and advice.

To fit these to standard conrods, please see the 18mm little end bushes to make the gudgeon pin fully floating. The special wire circlips included with the pistons then hold the gudgeon pins in place. Alternatively, upgrade to our MED steel conrods for a direct fit.

We would highly recommend purchasing an MED piston installation tool for trouble-free insertion to the bores.

Additional Information

How to machine standard little ends

1. Fit 18mm bushes to little ends and hone to a finished size of 18.015mm-18.020mm.

2. Machine little end of conrod on the short side to give a finished width of 21mm.

3. Drill 1/8-inch hole through the little end and bush at the top of the conrod.

4. Lightly countersink this holes allow oil feed to gudgeon pin.

Running clearances

We would recommend a skirt clearance of 0.004", however different engine builders will have their own preferences.

The recommended ring gap is 0.010"-0.012".

Compression height

We keep a wide range of piston sizes and compression heights to suit all manner of engine builds. Here we give the option of 1.248", or super short 1.115".

This is primarily to allow the use of longer conrods and/or longer stroke crankshafts, however it can also be useful if the block face requires extensive machining of if you wish to lower the compression ratio by increasing the deck clearance.

Please contact us for further advice if you are unsure.

Forged vs diecast

Omega forged pistons are stronger yet lighter than our diecast range, making them particularly well suited to higher performance applications. They are specifically designed for high RPM competition engines.

Forged pistons utilise a smaller, lighter 18mm floating gudgeon pins, which give less chance of damaging the pistons on insertion, and are easier to disassemble than press-fit pins.

As a general rule, opt for forged pistons if you wish to exceed a static compression ratio of 11:1, have a very high performance engine or wish to run high boost levels on a forced induction setup.

Conrod compatibility

We'd highly recommend using these pistons with MED steel conrods, as they come with an 18mm bushed little end to suit. If your race regulations or budget do not allow the use of MED steel rods, the standard conrods can be modified with 18mm bronze bushes (please see above).

Production process

High silicone alloy is first cut to billet size and the faces machined to a smooth finish. Each billet is pre-heated in an air-circulating furnace to a temperature close to the operating temperature of the piston crown, then compressed into a rough shape using Omega's in-house forge and custom-designed dies.

The specific temperature, together with tightly controlled speed of the forging process, gives a dense and very fine grain structure to the piston for high strength and superior fatigue life.

Any excess material is then removed before the forgings are heat-treated and wet blast cleaned. From here each piston is subject to a highly developed process of CNC machining, with constant measurement and quality control checks by experienced perfectionists.

Once final machining is complete, the pistons are engraved with a model and batch number, cleaned and sorted into matched weight sets. It's a time-consuming process to create such a high quality product, but the end results are well worthwhile.

Frequently Asked Questions

Which compression height do I need?

The 1.248" height pistons (measured from gudgeon pin centre to crown top) are ideally suited to using 6" conrods, as this maintains the same overall stroke length as a standard setup. The special 1.115" pistons are intended to be used alongside an 86mm stroke crankshaft and 6" rods, for a 1460cc engine.

What is the recommended bore clearance and piston ring gap?

For forged Omega pistons we would recommend a skirt clearance of 0.004". The largest diameter of the piston should measured with a micrometer, 90-degrees to the gudgeon pin, three quarters of the way down the skirt. The recommended ring gap (top and second ring only) is 0.010-0.012".

Is there a recommended bore finish?

Yes, we suggest plateau honing with a cross hatch angle of 35-40 degrees. After honing with either conventional (#220 - #280 grit) or diamond stone (#325 - #550 grit), finish by smoothing the surface with a fine-grit conventional abrasive (#400 - #600 grit) or sweep the bores with a flexible brush or a nylon bristle plateau honing tool. This is necessary to get rid of jagged peaks and folded and torn material. Your machine shop may have different preferences.

Which conrods do these pistons suit?

These are designed to fit with a bushed 18mm little end diameter in a fully floating setup, whether that's an aftermarket steel conrod or a standard conrod modified with a set of MED-1018-LB bushes. Ideally these are paired with 6" long conrods, or else you will need to machine a large amount from the top of the block to achieve a suitable deck clearance with standard 5.750" conrods. This can lead to further complications such as pushrod length and rocker geometry setup.

What is meant by 'fully floating'?

Rather than being fixed in place, the gudgeon pins can move and rotate in the conrod little ends, with the piston held to the pin by a pair of wire clips. The fully-floating setup is preferred by race engine builders for ease of assembly/disassembly, while there is also less chance of damaging the pistons on assembly.

Can you tell me what compression ratio these pistons will give?

The pistons are only one part of the equation, so it would be inaccurate to supply a static compression ratio figure without knowing more information on the engine build. If you can email us with the cylinder head chamber volume, head gasket type and the deck clearance figures, we will be able to calculate this for you, and make further recommendations.

Are these only suitable for race engines, or can I use them on the road?

It depends - these are predominantly used in competition A-Series engines, where the higher operating temperatures give a greater expansion rate. As such, they will run marginally larger bore clearance to our range of Omega diecast pistons. If the engine is built to a similar spec to a competition engine then it will be absolutely ideal on forged pistons. For more mild engines you may prefer to look at our range of diecast pistons instead.

What's the advantage of forged Omega pistons over diecast versions?

Weight - these are considerably lighter than an equivalent diecast piston, as more material can safely be removed as part of the intricate machining operations. The additional strength allows for the use of a lightweight 18mm gudgeon pin, itself saving 29g a piece compared to the 13/16" standard diameter pin. For any high RPM A-Series engine, saving weight is vital. These are also better suited to compression ratios over 11:1.

How much do these forged pistons weigh?

The weight will vary depending on your chosen spec. As an approximate guide, including the ring pack and gudgeon pin, single piston weights are as follows: 1.248" flat top, 299g, 1.248" 7cc, 272g, 1.115" 7cc, 266g. Each boxed set is weight matched within 0.5g. The piston weight may vary from one production batch to another, so please contact us at the time of order for the most accurate measurement.

Related Products