MED EN40B CRANKSHAFT KIT - MINI

Description

The MED crankshaft is CNC machined from EN40B steel billet and nitride hardened, with extra large C-shape counterbalance webs to reduce potentially damaging harmonics.

Cooper S size big end journals with counter-bored webs reduce weight and further enhance the counterbalance effect. An improved counterbalance helps to reduce the 'whip' often encountered with the three main bearing A-Series crankshaft, to improve longevity and performance at higher RPM levels.

This crankshaft kit is ideally suited to race series such as Mini Miglia and Appendix K historics where a more traditional stroke length and big end size must be retained. It would also suit high performance road, rally and trackday builds.

Each kit includes an EN40B steel crankshaft, matching steel conrods, forged Omega pistons and ACL Race bearings.

Crankshaft kit contents;

- MED 81.33mm EN40B steel crankshaft

- MED steel conrods

- Omega forged lightweight pistons

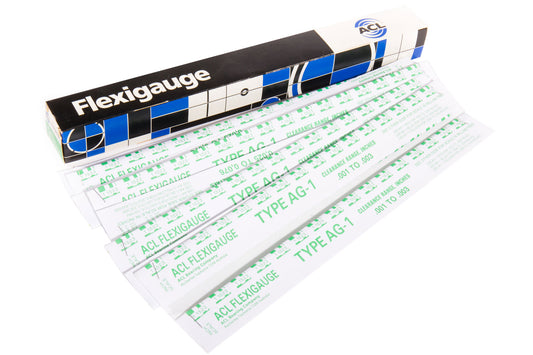

- ACL Race main bearings

- ACL Race big end bearings

- ACL thrust washer set

Kit options;

- 5.750" or 6.000" conrod length

- 1.498" or 1.248" compression height pistons

- +20, +40, +60 or 73.5mm piston diameter

- Flat top or dished pistons

- A-Series or A+ main bearings

Please select your chosen engine capacity, piston crown type and conrod length from the dropdown menu. If you would like further information or advice, please get in touch.

Please note - the timing gear end has a carefully machined radius for extra strength - please be sure that your timing gear sprocket has a matching radius or damage will be caused on assembly.

If you're not restricted by race regulations, you may be interested in upgrading to the more radical MED Multiweb crankshaft kit, which further improves the counterbalance effect.

Frequently Asked Questions

Why is an MED steel crankshaft better than a standard type?

Our cranks are lighter, stronger and better balanced. Most factory crankshafts were made from lesser grade EN16T, as opposed to certified EN40B steel billet. The counterbalance effect is far greater with this design, so it is both stronger and better balanced. An improved counterbalance effect helps to reduce the 'whip' often encountered with the three main bearing A-Series crankshaft, to much improve longevity and performance at higher RPM levels.

How does a new steel crank compare to a re-worked standard Mini crankshaft?

Whilst standard crankshafts can be effectively re-worked to improve their counterbalance effect, it is not possible to add material, only subtract. You're also unlikely to know the history of a second-hand crankshaft - it could be over 60 years old!

Is a steel crankshaft lighter than a standard crankshaft?

Yes - standard 1275 Mini crankshafts weigh between 11.5kg-12kg, and this weighs just 10.5kg. A heavily modified factory crank could potentially weigh less, however, but it is unlikely to have the weight in the right places for the benefits of strength and balance.

What's better, steel billet or forged classic Mini crankshafts?

We've tried both and have found no tangible difference in strength and reliability between the two manufacturing techniques. Our preference is to have crankshafts CNC machined from EN40B steel billet, as this allows for regular design development without needing to make a new forging tool each time, which would not be economically viable.

I'm unsure which combination of pistons, conrods and crankshaft I need - can you help?

Yes, please contact us via email or phone and we'll be happy to help further. Simply let us know what compression ratio you are aiming for, or if you're not certain, the general engine spec and usage. We can put together many different combinations to best suit your engine build plans.

Does this come with any certification?

Absolutely. Each crankshaft is supplied with a test report, fully balanced, 100% crack detection and with certification of material and heat treatments. Critical detail inspection reports are also supplied. There is an incredible amount of work involved in producing, machining and testing each crankshaft, using Arrow Precision's 50-plus years of specialist experience.

What makes the MED conrods better than standard?

There's three benefits - strength, light weight and high quality. H-section steel conrods are considerably stronger than mass-produced standard conrods, which were never designed for high performance applications. Standard conrods can be lightened and balanced, but even then our steel conrods will be lighter and stronger. The highly accurate production process allows for exact build tolerances; you will not find a higher quality A-Series conrod.

Am I better with 6.000" conrods or 5.750"?

This is the length from the centre of the big end journal to the centre of the little end journal. As standard on a 1275cc A-Series this is 5.750". Changing to a longer conrod and shorter piston will maintain the same overall length, but offer a reduction in friction in the engine and give a marginally longer piston dwell time at TDC. Overall this is considered a performance improvement, but it's only useful if the race regulations allow a non-standard rod length.

Do I need to run steel main caps with this steel crankshaft package?

Ideally upgrade the standard main caps to a four-bolt steel centre main set, yes. We consider this a must-have for any competition A-Series engine, as the three-main-bearing design of the crankshaft is particularly prone to 'whip' at high rpm.

I'm unsure which combination of pistons, conrods and crankshaft I need - can you help?

Yes, please contact us via email or phone and we'll be happy to help further. Simply let us know what compression ratio you are aiming for, or if you're not certain, the general engine spec and usage. We can put together many different combinations to best suit your engine build plans.

Related Products