MED MINI STEEL MAIN CAP SETS

Description

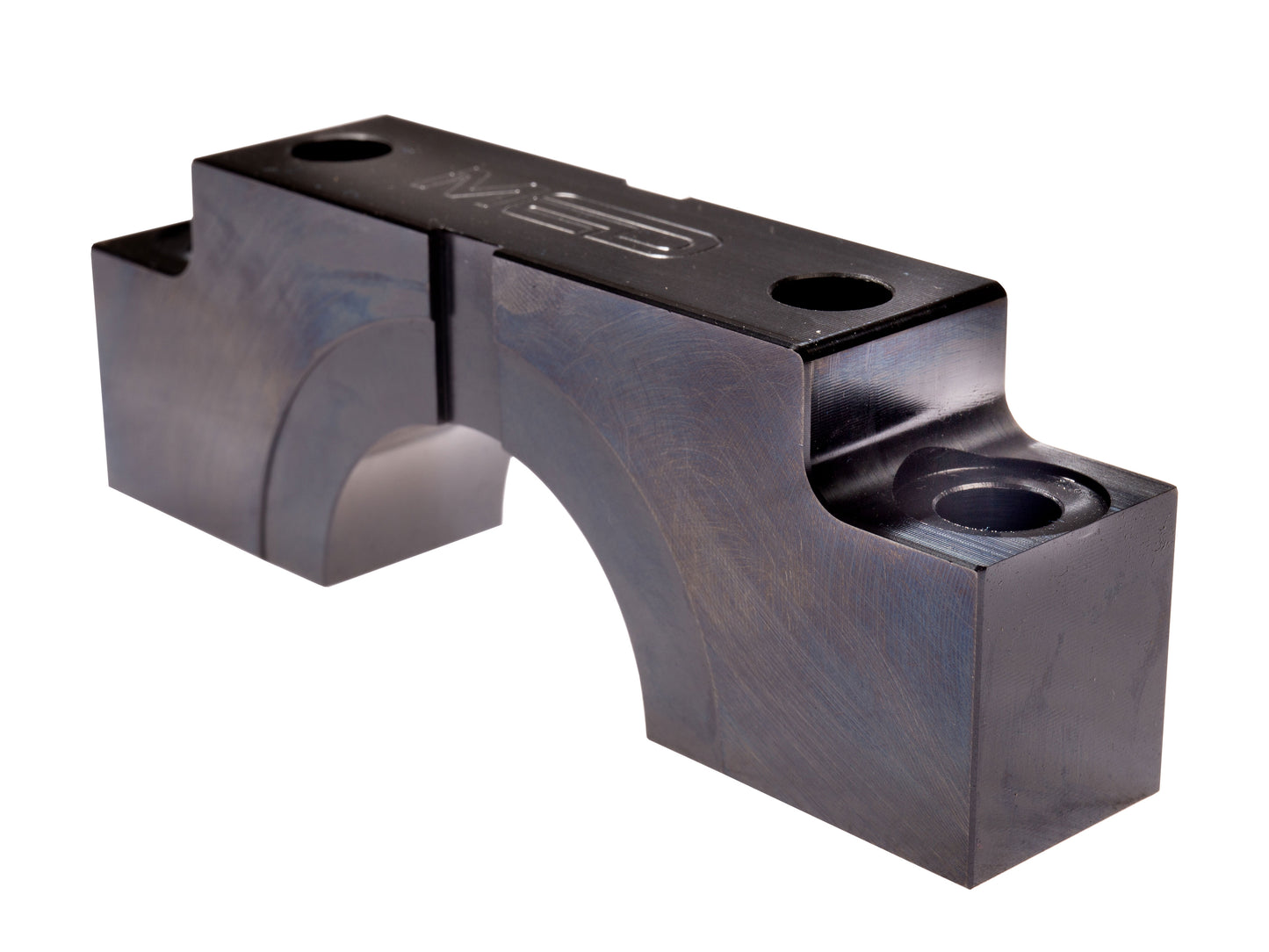

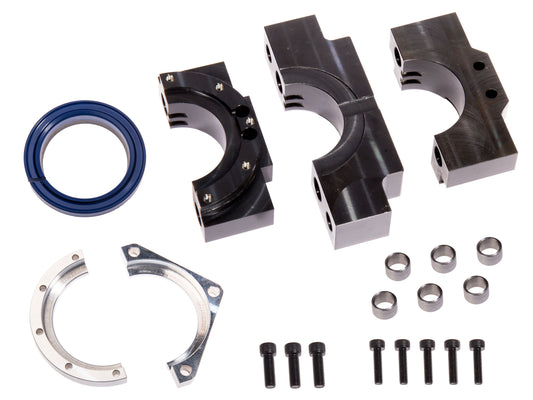

A must for any competition A-Series engine, the MED steel main cap set adds much strength to the block, with a four-bolt centre cap where the crankshaft is particularly prone to 'whip' at high rpm.

The standard main caps have a tendency to float at high RPM/loads, often evidenced by chatter marks on the block. This kit improves overall reliability of the engine, aiming to eliminate this movement, reduce flex of the crankshaft and increase durability of the main bearings.

Designed for all 1275 Mini engines (excluding the original Cooper S), our caps are CNC machined in the UK from EN8 steel stock and supplied with a set of six dowels.

Please note, the block will need to be drilled/tapped to accept the extra centre cap fixings and then line-bored.

We'd highly recommend using the MED AFS main stud conversion rather than standard bolts, which is designed specifically to suit these caps.

Frequently Asked Questions

Will MED steel main caps fit all Mini A-Series engines?

These are designed to fit 1275 blocks, including both A-Series and A+ varieties, but excluding the original 1960s Cooper S blocks, which had studs and steel caps from the factory. They will fit other transverse A-Series engines such as Metro and Austin 1300GT too. For inline applications we keep a different set of steel main caps to suit.

What is the fitting procedure?

We would recommend starting with the MED AFS stud kit, modifying the block to accept the four-bolt centre main and checking, drilling and tapping the existing threads to level-up the studs. From here, the block and caps will need to be line-bored and hone finished by a specialist machine shop, with the thrust washer faces machined flush to the block.

Can I fit steel main caps to a road-going Mini engine?

Sure, if the budget allows. These come highly recommended for any high RPM A-Series; we'd consider them essential on a competition engine that's driven to sustained high RPM levels.

Do I need to install a steel crankshaft to suit the main caps?

No, the standard 1275-type crankshaft with 2" main journals will also fit. Although most engine builders opting for steel main caps would usually install a steel crankshaft too.

I have lost the original A-Series main caps - does this matter?

No, as long as the block is not damaged, then it will be ideal for a steel main cap conversion, as the original caps can be discarded anyway.

Do I need to install a full set of steel main caps?

We can supply the centre four-bolt main cap as a separate item, but generally it is recommended to fit a full set, as the machining cost and time will be very similar.

Will I need A-Series (side tang) or A+ (centre tang) main bearings?

The MED steel main caps feature provisions for both styles of retaining tang, so you can use either A-Series or A+.

What should the finished bore size be after machining?

Your machine shop should be able to confirm this, however if you would like further clarification, please email us and we can advise.

Will line-boring the block affect other dimensions in the engine?

Line-bored correctly, the block's main journal bores should barely be touched by the line-boring operation, so it should not affect tolerances elsewhere. We have heard of engines in the past where the line-boring operation removes too much material from the block itself, which can give problems with drop gear engagement and a slack timing chain. Double check this with your chosen machine shop to avoid issues.

Related Products